Basic Knowledge of Cosmetic Spray Pumps

A cosmetic spray pump is essential for atomizing and evenly distributing liquid cosmetics, commonly used for , makeup, hair care, body care, and s. Its structure typically includes a pump head, nozzle, pump body, piston, spring, and straw. When pressed, the pump head generates pressure within the piston, releasing the liquid through the nozzle as a fine spray. This design provides accurate metering, strong sealing, and a comfortable, efficient user experience. Cosmetic spray pumps prioritize material safety, spray quality, and durability, making them ideal for a variety of cosmetic applications such as skin care bottles, atomizers, and more.

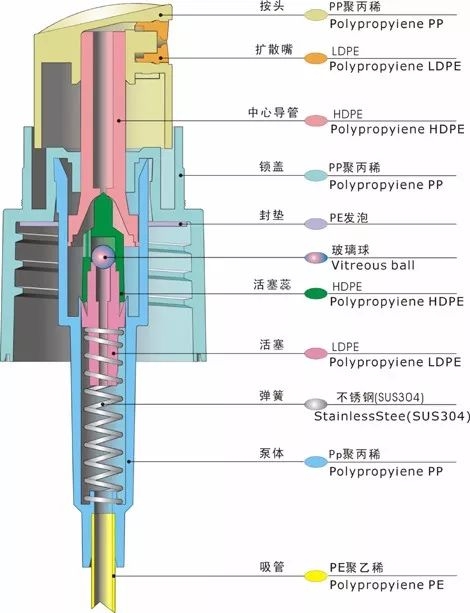

1. Molding ProcessCosmetic sprayer pumps, whether for skincare or makeup products, are usually made from durable plastics like PE, PP, and LDPE, with parts like springs sourced externally. Here’s a breakdown:

Mold Design & Manufacturing: Molds are crafted to meet pump structural needs using CNC machining and EDM.

Material Preparation: Plastics are dried to avoid bubbles in the final product.

Injection Molding: Heated plastic is injected into the mold to cool and take shape.

Secondary Processing: Parts undergo finishing and assembly, including pump bodies, springs, pistons, and nozzles.

Quality Inspection: Appearance, function, and durability tests ensure reliable metering and sealing.

This streamlined process, often used for cosmetic sprayers, pumps, and atomizers, is crucial for efficiency in production.

2. Surface TreatmentSurface treatment improves appearance and texture. Methods include:

Plating: Vacuum or electroplating enhances durability and adds metallic luster.

Spraying: Options like spray painting and UV curing create various colors and textures.

Printing & Engraving: Techniques like silk-screen, pad printing, and laser marking allow for customized branding.

Polishing & Coating: Electrophoretic coating and water transfer printing offer protective layers and unique designs.

These techniques add aesthetic appeal and durability, making the product competitive in cosmetic markets.

The core components of a cosmetic spray pump include:

Pump Head: Controls the pump mechanism.

Nozzle: Atomizes the liquid; design affects spray particle size.

Piston: Presses and releases liquid, working with the pump head.

Pump Body: Houses key parts, ensuring durability.

Spring: Helps return the pump head to position.

Dip Tube: Draws liquid from the bottle base.

Bottle: The container for the cosmetic liquid, such as bottles or plastic bottles in varied capacities.

Together, these components ensure the smooth function of the spray pump, often used for perfume atomizers, lotion bottles, or skin care bottles.

The spray pump’s function relies on pressure and liquid dynamics:

Pressing the Pump Head: Creates pressure, causing liquid to move through the nozzle.

Atomization: The nozzle’s design atomizes the liquid into a fine mist.

Release and Refill: The spring resets the pump, allowing the bottle to draw more liquid for the next use.

This principle, often seen in atomizers and lotion pumps, provides continuous, efficient spray distribution.

The caliber and metering of spray pumps, crucial for user experience, vary based on product needs:

Standard Caliber Sizes: Common sizes like 18/410, 20/410, and 28/410 meet different product needs.

Metering Options: Includes push-to-meter and continuous spray, allowing for precise dosage control, from to perfume applications.

By selecting appropriate nozzle and pump body designs, products can be tailored for specific effects, such as a fine mist for perfumes or a broader spray for body care.

Spray pumps are versatile and widely used for:

Skincare Products: Ideal for toner, lotion, and essence sprays, providing even coverage.

Makeup: Setting sprays and primers benefit from spray pumps’ even distribution.

Hair Care: Used for hair sprays, conditioners, and styling products.

Body Care: Common in body lotions, sunscreens, and moisturizing sprays.

Perfume: Precision spray for perfume bottles to ensure controlled application.

Cleaning Products: Cleansing sprays and disinfectants are also popular uses.

Spray pumps are highly favored in cosmetic packaging due to their convenience, controlled dosing, hygiene, and portability. This makes them essential for modern cosmetic products, enhancing the appeal and functionality of skin care bottles, lotion pumps, and other personal care products.