How to Choose a Suitable Pump for Your Product?

The skin care pump is a precision dispensing device designed to provide users with an accurate, hygienic and convenient use experience. It can take out the right amount of product by pressing the pump, avoiding the pollution and waste that may be caused by the traditional bottle opening method. In addition, the modern pump design also focuses on protecting the stability of the product, preventing oxidation and deterioration, thereby extending the shelf life of skin care products and ensuring the best skin care results every time you use it. So, do you know how to choose the right pump?

Ordinary Lotion Pump

It is commonly used in daily chemical products such as shampoo (lotion), shower gel (lotion), conditioner, body lotion (lotion), facial cleanser, hand soap, dishwashing detergent, laundry detergent, disinfectant, mouthwash, as well as general cosmetics such as hand , , essence, sunscreen, and liquid foundation.

Ordinary lotion pumps usually come with a hose, and the pumping volume is generally 1.0-5.0ml/ time, which is often suitable for materials with good fluidity / low viscosity. Materials with poor fluidity / high viscosity require specially designed lotion pumps, such as high-viscosity lotion pumps.

The decoration of ordinary lotion pumps is relatively simple, and common processes include: adding an aluminum oxide cover,electroplating, printing, hot stamping, etc.

Lotion pumps have a very wide range of uses. Whether customers choose lotion pump products or manufacturers recommend lotion pumps to end customers, some factors need to be considered for reference when making a choice.

1. Select according to the compatibility of the raw materials and liquid of the emulsion pump

Must be able to pass compatibility testing.

2. Select according to the range of pump output

Before the end product is launched on the market, there is usually a consumer survey phase, which basically gives a preliminary recommended usage amount. Based on this usage amount, the specifications of the lotion pump can be selected accordingly, or the integer number of pumping times of the pumping amount can reach the recommended usage amount. Generally: recommended usage amount = (1-2) * pumping amount.

For example: if the recommended usage is 1.0 ml/ time, you can choose a lotion pump with a pumping volume of 1.0 ml/ time, or you can choose a lotion pump with a pumping volume of 0.5 ml/ time.

3. Select according to the final form

After confirming the packaging capacity, select the specifications of the lotion pump based on the packaging capacity and the expected number of uses. Generally, one package can be used 100-300 times.

Example 1: For a 100ml bottle, a lotion pump with a specification of 1.0ml/ time can be selected, which can be used about 100 times, or a lotion pump with a specification of 0.5ml/ time can be selected, which can be used about 200 times.

Example 2: For a 500ml bottle, a 2.0ml/ time lotion pump can be selected, which can be used about 250 times, or a 3.5ml/ time lotion pump can be selected, which can be used about 140 times.

4. Select according to the caliber specifications of the lotion pump and bottle.

Lotion pumps and bottle mouths are generally matched with screw threads, and there is a common standard in the industry. Generally, suppliers produce lotion pumps according to this standard, and customers select lotion pumps according to this specification.

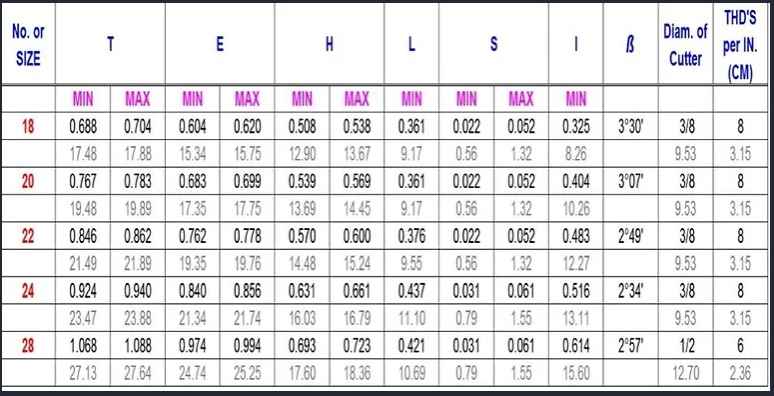

Common calibers are 18mm, 20mm, 22mm, 24mm, 28mm, 33mm, and 38mm;

Common specifications are 400, 410, and 415.

Standard example:

Plastic Bottle Finish SP - 410

List of common lotion pump size specifications

5. Selection according to the viscosity / fluidity characteristics of the liquid

/ Fluidity of the liquid, the product terminal will have specific data, but for emulsion pump manufacturers, this data is lacking.

Usually, you can pour the liquid into the beaker and judge based on the liquid level:

1. The liquid level can be horizontal in an instant without any trace on the liquid surface. All emulsion pumps and derivative pumps can be used. You only need to consider the characteristics of the liquid formula to choose the appropriate one.

2. The liquid surface can quickly reach horizontality, but there are slight traces of accumulation on the liquid surface. The spray pump needs to verify its spray effect. Other emulsion pumps and derivative pumps can be used.

3. If the liquid surface can reach a horizontal level within 1-2 seconds and there are obvious signs of piling up on the liquid surface, you need to use a lotion pump with strong suction and spring elasticity. High-viscosity pumps are preferred, followed by airless cans / bottles for packaging.

4. There are obvious signs of stacking on the liquid surface and it cannot reach a horizontal state in a short time. High-viscosity pumps also need to be verified. It is preferred to use airless cans / bottles for packaging, or choose lid packaging.

5. Invert the beaker containing the liquid. The liquid cannot be poured out in a short time. Only airless tanks, or other packaging forms such as lids, hoses, cans, etc. can be used.

Other Pump Options

Choice of airless pumps, spray pumps, foam pumps, large output pumps, oil pumps, metal pumps, toothpaste pumps, high viscosity pumps, all-plastic pumps, anti-counterfeiting pumps and more.

Airless Lotion Pump

It often appears with matching bottles, cans, hoses, etc. to ensure that the contents are completely isolated from the air during use. Airless lotion pumps and supporting products are mainly suitable for products that contain volatile substances that are easily affected by air and deteriorate, and are commonly found in mid- to high-end cosmetic packaging.

Airless emulsion pumps usually have no hoses, and the pumping volume is generally 0.2-1.0ml/ time, which can be used for materials with poor fluidity or high viscosity.

The decoration and structure of airless emulsion pumps are relatively rich, such as: adding an aluminum cover, electroplating, spraying, hot stamping, printing, laser, labeling, sandblasting, etc., as well as a double-layer structure with a transparent shell, a double-head structure (two materials at both ends), a double-cavity structure (two bottles and two pumps in one package), etc., to provide packaging options for mid- and high-end products.

Spray Pump

It is a pump product that sprays the contents in atomized form. According to the design that matches the bottle mouth, it can be divided into tie-mouth type and screw-mouth type. According to the product function, it can be divided into ordinary spray pumps, valve (pump type), spray guns, etc.

Spray pump products are mainly suitable for the packaging of water-related products such as toner, , floral water, disinfectant, gel water, air freshener, collar cleaner, detergent, insecticide, etc. Some spray pumps can also be used in the packaging of thinner products such as liquid foundation, sunscreen, BB liquid, etc.

Spray pumps usually come with a hose, and the pumping volume is generally 0.1-0.3ml/ time, and there are also pumping volumes of 1.0-3.5ml/ time.

Common decorations for spray pumps include: adding an aluminum oxide cover, electroplating, spraying, printing, hot stamping and other processes.

Foam Pump

A foam pump is a dispensing device specially used to convert liquid skin care products into foam. It is usually equipped with a hose and the pumping volume is generally 0.4-1.0ml/ time. It is widely used in skin care products such as facial cleansers and shower gels. The foam pump can produce rich and delicate foam by pressing the pump, which improves the user experience and saves product usage.

Structure:

Pump: The pressing part, usually made of plastic or metal, is ergonomically designed for ease of use.

Pump tube: The tube connecting the pump and the bottom of the bottle, used to transport liquid products.

Foaming net: Located inside the pump, used to convert liquid into foam.

Valve system: controls the flow of liquid to ensure even foam at every pump.

Sealing ring: located at the connection between the pump and the bottle mouth, to prevent air from entering the bottle and protect the stability of the product.

Base: The base of the pump, connected to the bottle mouth to ensure the stability of the pump.

Characteristic:

Efficient foaming: The specially designed foam net and valve system can quickly transform liquid into rich and delicate foam.

Save usage: The foam pump can effectively control the amount used each time, avoid waste, and extend the service life of the product.

Easy to use: push-type design, simple operation, suitable for daily use.

Hygiene and safety: avoid direct contact with liquids, reduce the risk of contamination and keep the product pure.

Even distribution: Each pump produces even foam for consistent results.

Application:

Facial cleansing products: used in facial cleansing foam to provide rich foam, effectively cleanse the face and enhance the cleansing experience.

Shower gel: Used in foam shower gel to facilitate full body cleansing and bring a comfortable bathing experience.

Hand Sanitizer: Suitable for foam hand sanitizer, providing fine foam to effectively clean hands.

Baby products: used in baby foaming shampoo and shower gel, the gentle formula combines fine foam, suitable for sensitive skin.

Hair care products: Applied to foam conditioners to facilitate even application and enhance hair care effects.

Through its unique design and structure, the foam pump provides an efficient, convenient and hygienic use experience. It is widely used in a variety of skin care and cleaning products; meeting consumers' needs for product effectiveness and convenience.

Large Output Pump

As the name implies, it refers to a pump product with a relatively large pumping volume. It is commonly used in food packaging, such as ketchup, salad dressing and other food packaging with a certain fluidity.

Large-volume pumps generally also come with hoses, with a pumping volume of 5-20ml/ time.

Oil Pump

The oil pump of a skin care bottle is a device specially used to dispense oil-based skin care products. It is designed to provide a precise, hygienic and convenient way of taking them out. The oil pump can not only effectively control the amount used, but also protect the product from contamination and oxidation, extend the shelf life of the product, and enhance the user experience.

Structure:

Pump: The pressing part, usually made of plastic or metal, is ergonomically designed for ease of use.

Pump tube: The tube connecting the pump and the bottom of the bottle, used to transport oil products.

Valve system: controls the flow of oil, ensures accurate amount of oil each time you press, and prevents leakage.

Sealing ring: located at the connection between the pump and the bottle mouth, preventing air from entering the bottle and protecting the product from oxidation.

Base: The base of the pump, connected to the bottle mouth to ensure the stability of the pump.

Characteristic:

Precise control: The pump design can provide precise dosage to avoid waste.

Leak-proof design: Built-in leak-proof system ensures the cleanliness of the bottle and the usage environment.

Anti-oxidation: effectively isolate air and extend the shelf life of oil-based skin care products.

Easy to use: Push-type design, easy to operate, suitable for daily use.

Efficient Distribution: Evenly distributes skin care oil to ensure consistent amount every time.

Application:

Essential Oil: Suitable for high concentration essential oil to ensure product efficiency and stability.

Facial Treatment Oil: Used in facial treatment oils to prevent oxidation and keep the product pure.

Body care oil: Suitable for body care oil, convenient for large-area application, improving the use experience.

Massage Oil: Used in massage oil bottles to control the amount and avoid waste.

Hair Oil: Suitable for hair oil, which allows users to accurately control the amount and ensure even application.

The oil pump of the skin care bottle achieves an efficient, precise and hygienic use experience through its unique structure and design, providing a reliable solution for the application of various oil skin care products.

Metal Pump

Metal pumps are a high-end skin care product packaging solution, commonly used in high-end skin care products such as essences and lotions. Metal pumps are not only elegant in appearance and high-end in texture, but also have superior functions, ensuring the stability and efficiency of the product, and providing users with an excellent experience.

Structure:

Pump: Made of metal material, it has texture and durability, and is usually beautifully designed and ergonomic.

Pump tubing: The tube that connects the pump to the bottom of the bottle, usually made of plastic or metal, to ensure smooth liquid delivery.

Valve system: The precisely designed valve system controls the flow of liquid to ensure accurate amount of liquid each time you press the button.

Sealing ring: located at the connection between the pump and the bottle mouth, to prevent air from entering the bottle and protect the stability of the product.

Base: The base of the pump, ensuring that the pump fits tightly against the bottle mouth to prevent leakage.

Characteristic:

High-end appearance: Metal material brings high-end texture and visual effect, enhancing the overall image of the product.

Strong durability: Metal pumps are resistant to wear and corrosion and have a long service life.

Leak-proof design: The precise valve system and sealing ring design ensure that the product does not leak and keep the bottle and the use environment clean.

Precise dosage: Each press provides an accurate dosage, avoiding waste and overdosage.

Anti-oxidation: effectively isolate air, extend the shelf life of skin care products, and maintain the purity and stability of the products.

Application:

High-end essence: used for high-end essence, providing precise and hygienic way of taking, thus enhancing product value.

High-efficiency lotion: Applicable to high-efficiency lotion products to ensure consistent usage amount each time and enhance the effect of use.

Oil: Applied to beauty oil to prevent oxidation and keep the oil pure and highly effective.

Anti-aging products: Used in anti-aging products to provide precise control and ensure the stability and effectiveness of active ingredients.

Hair Care Essence: Suitable for high-end hair care essence, which allows users to accurately control the dosage and improve the usage experience.

With its excellent design and superior performance, metal pumps provide an ideal packaging solution for high-end skin care products, which not only enhances the appearance and texture of the products, but also ensures the efficiency and stability of use.