Basic Knowledge about PET Bottles

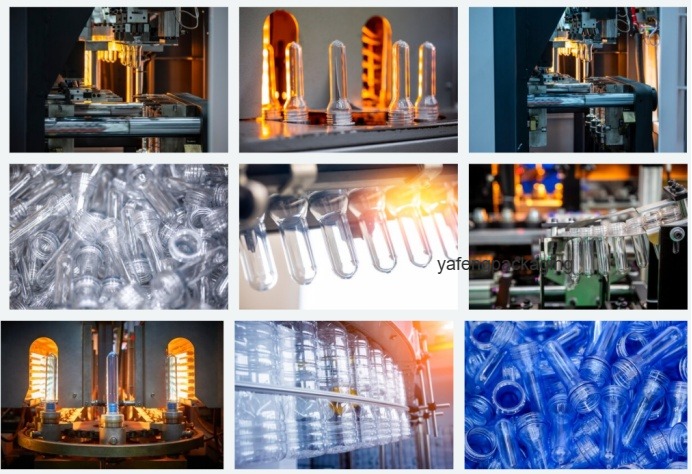

PET bottles refer to plastic bottles made of PET polyester as raw materials through injection molding and blowing. PET bottles have strong applicability and are widely used in food packaging, daily chemical packaging, pharmaceutical packaging and other fields, such as cosmetic bottles, beverage bottles, mineral water bottles, medicine bottles, etc. The preform is an intermediate semi-finished product for subsequent biaxial stretch blowing, and some of its factors affect the quality of the injection molded product.

1. Characteristics of PET bottles

Under a certain temperature and pressure, the mold is filled with raw materials, and under the processing of the injection molding machine, it is processed into a bottle preform with a certain thickness and height corresponding to the mold. PET bottle preforms are processed again through blow molding to form plastic bottles, such as cosmetic bottles, beverage bottles, mineral water bottles, etc. This bottle making method is called a two-step method, that is, the bottle preform is formed through injection molding, and then blow molded again to form a PET plastic bottle. Methods.

2. PET packaging advantages

① Has good mechanical properties. The impact strength is 3 to 5 times that of other films, and the folding resistance is good;

② Have stable chemical properties. Resistant to oil, fat, acrylic acid, dilute alkali, and most solvents;

③ Has excellent high and low temperature resistance. It can be used in the temperature range of 120℃ for a long time, can withstand high temperatures of 150℃ and low temperatures of -70℃ in short-term use, and has little impact on its mechanical properties at high and low temperatures;

④ Has excellent barrier properties. Can block air, water, oil and odor;

⑤ Has excellent transparency. Can block ultraviolet rays and has good gloss;

⑥ Highly safe. It is non-toxic, odorless, hygienic and can be directly used for food packaging.

⑦ The recycling rate is higher than other plastics. When burned as waste, it is flammable due to its low combustion calorific value and does not produce harmful gases.

In view of the above characteristics, PET bottles are widely used in container design, such as beverage packaging, condiments, daily chemical products, pharmaceutical packaging and other fields.

3. Main application areas of PET packaging bottles

01. Applications in the field of food packaging

PET bottles, metal cans, paper-plastic composite packaging, and bottles are the four main packaging forms of beverage products at present. Among them, PET bottles have the advantages of stable structure, strong gas barrier, low water absorption, light weight and toughness, uniform thickness, good transparency and gloss, etc., and have occupied a major share of the beverage packaging market.

02. Application in daily chemical packaging field

At present, the packaging of cleaning products, personal care products, and even cosmetics products tend to be transparent. PET bottles have excellent properties such as high strength, light weight, and good transparency. The high transparency of PET bottles can display the look and feel and quality of the contents to the maximum extent, providing an excellent interface for products to "communicate" with consumers.

03. Applications in the field of pharmaceutical packaging

PET is not only a harmless resin, but also a pure resin without any additives. It has passed the inspection of quite strict food hygiene laws including the United States, Europe and Japan, and is considered to be qualified and safe. Pharmaceutical and food packaging materials. Moreover, PET has excellent chemical resistance and can be used for packaging of all items except strong alkali and some organic solvents.

PET materials follow the "3 R " (Reduce, reuse, recycle) development trend of packaging products and will be better recyclable and more environmentally friendly. The application fields of PET new materials continue to expand, which will provide enterprises with and bring more innovative and friendly value to users.