Polyethylene terephthalate (PET) is a highly versatile polymer widely used in a variety of industries, including the cosmetic packaging industry. Known for its durability, recyclability, and excellent performance characteristics, PET is a common material for skin care bottles, plastic bottles, bottles, and plastic jars. Its ability to maintain the integrity of packaging while offering eco-friendly benefits has made it a top choice for cosmetic packaging solutions.

Polyethylene terephthalate (PET) is a semi-crystalline thermoplastic polymer belonging to the polyester family. It is widely used for cosmetic packaging due to its unique combination of properties, such as mechanical strength, chemical resistance, and transparency. PET is commonly used to produce plastic bottles, PET bottles, PETG, and plastic jars for skin care packaging.

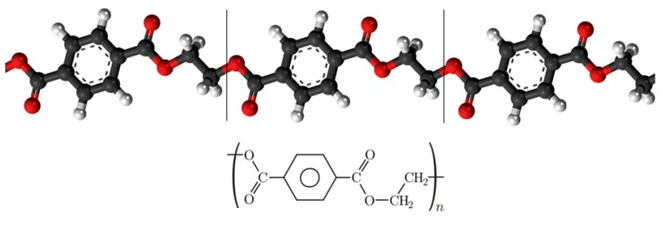

The chemical formula of PET is (C10 H8 O4) n. It is produced through a condensation polymerization process, typically derived from terephthalic acid and ethylene glycol. PET can be molded into nearly any shape, including PETG bottles and serum bottles, making it an ideal material for a wide range of cosmetic packaging applications.

PET’s desirable characteristics make it the material of choice for skin care bottles and other cosmetic packaging. These include:

Lightweight and Durable: PET is strong yet lightweight, making it easy to transport and cost-effective for packaging cosmetic products like plastic jars and plastic bottles.

Impact and Moisture Resistance: PET offers excellent resistance to impact and moisture, ensuring that serum bottles and other cosmetic packaging remain intact during use and storage.

Chemical Resistance: PET is highly resistant to alcohol, solvents, and oils, making it a perfect choice for skin care packaging that may come into contact with these substances.

Recyclability: PET is 100% recyclable and one of the most recycled materials globally. This makes it an eco-friendly option for sustainable cosmetic packaging solutions.

Clarity: PET is transparent, allowing for a clear view of the contents inside packaging, which is a critical aspect of cosmetic packaging for products like serum bottles and plastic jars.

PET can be easily processed using various methods such as injection molding, extrusion, and blow molding. Each of these methods is ideal for creating specific types of plastic bottles or cosmetic packaging.

Blow Molding: Blow molding is commonly used to create transparent plastic bottles for cosmetic products such as shampoos, s, and cleansers.

Injection Molding: This method is often used to produce precise plastic jars and cosmetic packaging containers. It ensures that the final product has a smooth finish and a strong, durable structure.

Extrusion: PET is extruded to produce sheets or films, which can be thermoformed for packaging purposes. PETG is another material often used in cosmetic packaging due to its improved processing properties.

Strength and Durability: PET offers superior impact resistance, making it less likely to break or shatter compared to packaging, which is particularly beneficial for products like skin care bottles and serum bottles.

Eco-Friendly: PET is 100% recyclable, and recycled PET (rPET) is increasingly used in cosmetic packaging to reduce environmental impact. By utilizing recycled PET (rPET) or post-consumer recycled (PCR) materials, cosmetic packaging companies can promote sustainability.

Lightweight: PET is significantly lighter than glass, making transportation more cost-effective and environmentally friendly.

Transparency: PET offers excellent clarity, which is ideal for showcasing products in skin care bottles, plastic jars, and other cosmetic packaging solutions.

Cost-Effective: PET is affordable, especially when considering its durability and recyclability, which makes it a popular choice for cosmetic packaging.

PETG is a glycol-modified version of PET, which improves its processing properties. PETG is particularly useful for cosmetic packaging as it enhances the material’s toughness and chemical resistance, while maintaining the recyclability and transparency that makes PET so desirable.

Advantages of PETG for Cosmetic Packaging:

Enhanced toughness and impact resistance.

Better chemical resistance, making it suitable for a broader range of cosmetic products.

Ideal for embossed printing and 3D printing designs on skin care bottles and cosmetic packaging.

Easier processing compared to standard PET, with a lower melting point.

The growing demand for eco-friendly packaging has driven the increased use of recycled PET (rPET) in cosmetic packaging. This process involves recycling post-consumer PET bottles into new packaging materials, reducing waste and the demand for virgin plastic.

rPET can be used to manufacture new cosmetic packaging containers, such as plastic jars and serum bottles, without compromising on quality.

Recycling PET helps conserve resources and reduces the environmental footprint of the cosmetic packaging industry. More companies are turning to PET bottles, PETG, and rPET to meet sustainability goals and consumer demand for green packaging solutions.

As demand for sustainable packaging increases, PET remains a leading material in the cosmetic packaging industry. Its versatility, recyclability, and ability to maintain product integrity make it an ideal choice for skin care bottles, serum bottles, plastic jars, and other packaging solutions. By adopting PET and rPET, brands can not only enhance the aesthetic appeal and functionality of their cosmetic packaging but also contribute to a more sustainable future.

With innovations in 3D printing and the rise of eco-friendly materials like PCR and recycled PET, PET’s role in cosmetic packaging will continue to grow, offering both and sustainability for the beauty industry.