Product Definition

Lipstick tubes are one of the most intricate and important types of cosmetic packaging. These tubes are made up of multiple components and serve as functional packaging solutions made from various materials. In terms of material composition, lipstick tubes can be divided into volatile and non-volatile types, with some being airtight and others not. Typically, lipstick tubes are filled using automated machines (such as front filling, rear filling, or direct filling). A poorly designed lipstick tube, with misalignment in the components or improper lubrication application, may lead to production stoppages or malfunctions.

Manufacturing Process

Basic Materials

Lipstick tubes are primarily made from full plastic, such as plastic lipstick tubes, or aluminum-plastic combinations. Common plastic materials include PC, ABS, , ABS+SAN, SAN, PCTA, and PP. For aluminum tubes, materials like 1070 and 5657 are frequently used. To maintain the brand's aesthetic, some lipstick tube manufacturers opt for premium materials like zinc alloy or sheepskin as accessories.

Molding Process

Plastic components of lipstick tubes, including the cap, base, and related accessories, are typically produced via injection molding, ensuring the precise shaping and functionality of the lipstick shell and its elements.

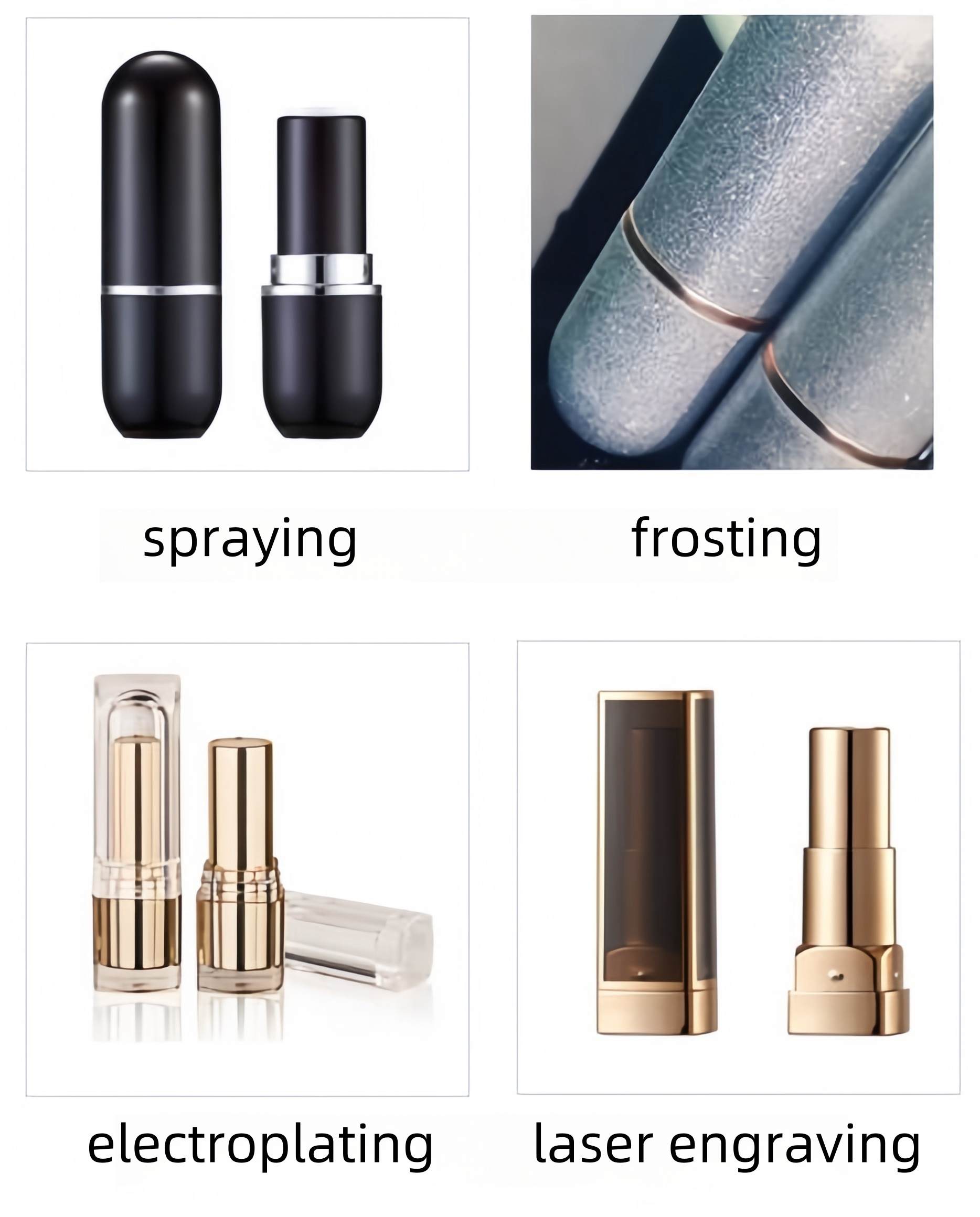

Surface Treatment

Various surface treatment processes are applied to lipstick shells. For plastic parts, methods such as spraying, electroplating, evaporation, laser engraving, and insert molding are common. For aluminum components, processes like anodizing and oxidizing electroplating are frequently used to enhance the tube’s durability and appearance.

Graphic and Text Printing

Cosmetic packaging design plays a key role in consumer attraction. The lid and base of lipstick tubes can be customized with logos, brand names, or other graphic elements using techniques like silk-screen printing, hot stamping, pad printing, heat transfer printing, or water transfer printing. These methods ensure the lipstick packaging stands out.

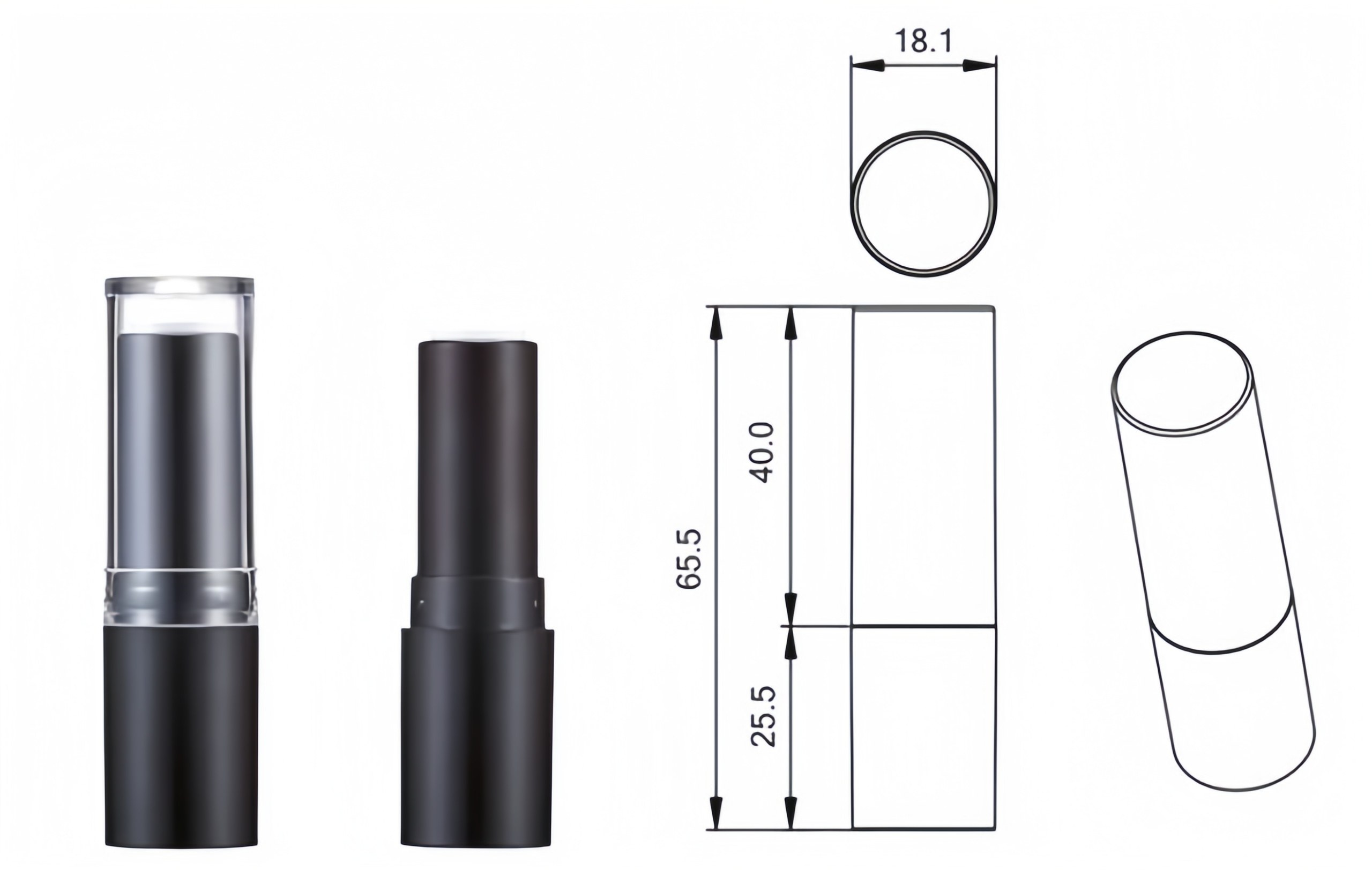

Product Structure

Product Classification

Lipstick tubes can be classified based on components like the cap, bottom, middle core beam, and other parts such as the cups, forks, and spirals. The middle beam is typically made from aluminum, which undergoes anodization for added strength and metallic texture, although some are made from injection-molded plastics. Lipstick tubes may also come in slim variations, lip gloss packaging, or lip balm packaging.

Cover

The cover of the lipstick tube can be made from various materials like aluminum, acrylic, or ABS. Aluminum caps are often used for their premium look, while some may also incorporate plastic to reduce costs.

Base

The base of the lipstick tube is usually made from acrylic or ABS plastic, with some brands adding weight by incorporating iron to enhance the lipstick tube's feel. However, iron-based adhesives may cause issues during transportation, potentially resulting in failures or poor customer experiences.

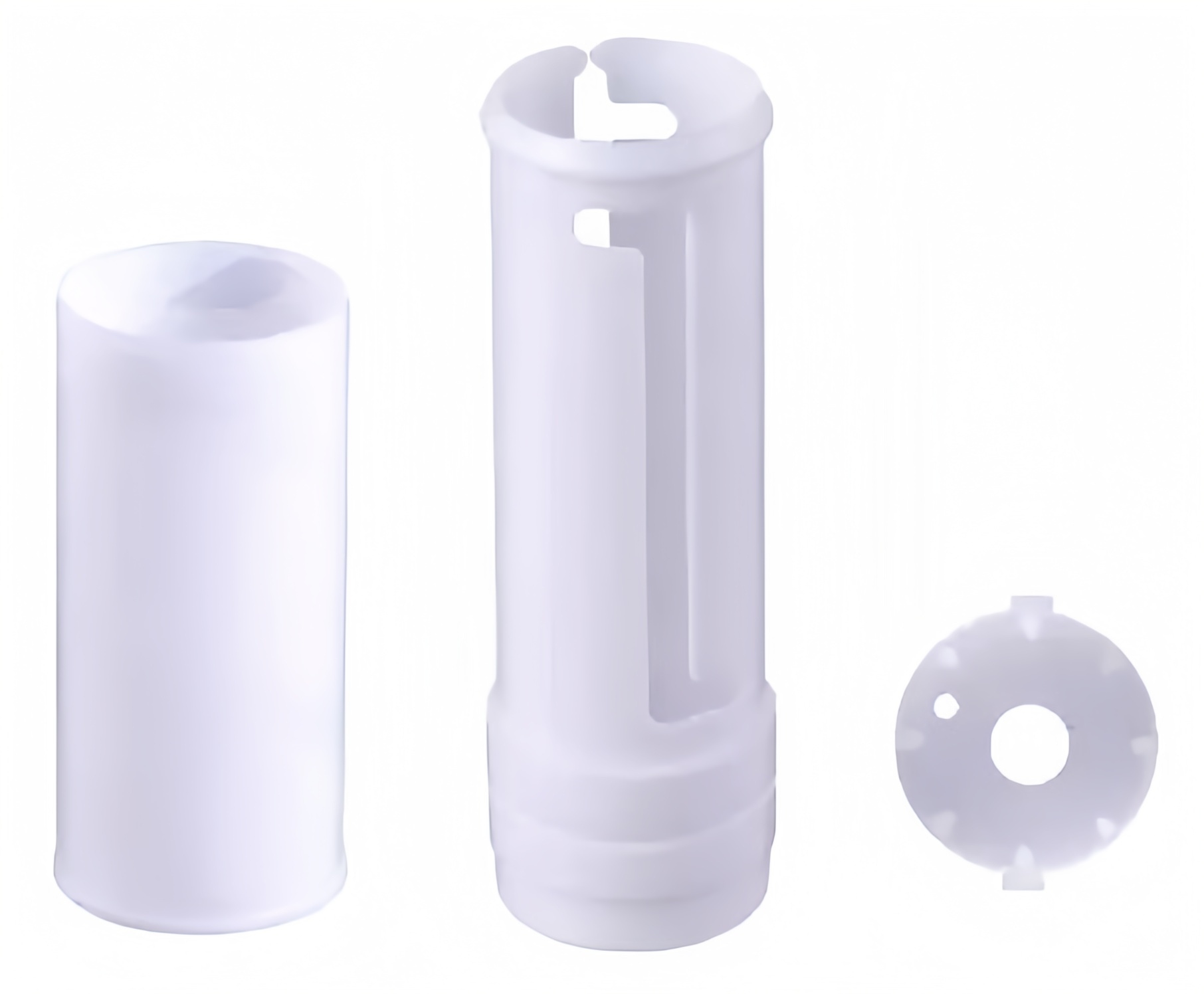

Mechanism Core

The mechanism core is the essential component of the lipstick tube, often compared to the heart of the product. It controls the functionality of the tube, including the lipstick shell's rotation, smoothness, and the upward movement of the lipstick tube's contents. The core components, like the screw and fork, enable efficient use and provide the necessary pressure to push the lipstick out smoothly. Lipstick tubes can have either a traditional screw system or a more advanced lubricant-free design. These parts must be carefully designed to ensure ease of use, durability, and a flawless customer experience.

Cosmetic Applications

As the name suggests, lipstick tubes are mainly used for packaging lipstick products. However, due to the growing popularity of other cosmetic products such as lip glosses, lip oils, and lip balms, many manufacturers have refined their packaging structures to accommodate these products as well. Cosmetic packaging solutions for these products often utilize a similar structural design, offering a full range of options for different types of cosmetic lipstick products.

Procurement Notes

Choosing a Lipstick Tube Supplier

When selecting a supplier for lipstick tube packaging, ensure that the supplier provides suitable and accurate drawings for the components of the tube, such as the snail core design. Choose suppliers with experience and stable production lines to avoid the risk of poor product quality or inconsistent performance.

Main Quality Control Indicators

The main quality control indicators for lipstick tubes include hand feel, compatibility with filling machines, transportation vibration resistance, air-tightness, material compatibility, size accuracy, and production capacity. It is crucial that the lipstick tube packaging meets the product's specifications and is ready for mass production.

Risks of Choosing Aluminum Lipstick Tubes

Aluminum lipstick tubes are sometimes chosen for their premium finish, but there are process limitations in the stretching and cutting stages. Poorly designed or sharp-edged aluminum tubes can pose safety risks. Testing equipment, such as sharp-edge testers and high-temperature resistant tape, should be used to assess potential hazards and ensure the product complies with safety standards.

Conclusion

Choosing the right lipstick packaging is crucial for cosmetic brands that aim to deliver a high-quality customer experience. Whether selecting a plastic lipstick tube, cosmetic lipstick packaging, or a more complex aluminum-plastic combination, it’s essential to focus on material selection, design accuracy, and functionality to ensure the tube performs well and enhances the product's appeal. Proper manufacturing processes, quality control, and supplier selection will result in a superior lipstick tube that offers both aesthetic and functional value for consumers.