There are many problems in production, among which blooming is an important technical problem. To deal with the blooming problem, it is necessary to understand the cause of the glass blooming and the state of the blooming, so as to facilitate prevention and solution.

1. Causes of glass blooming

The glass used in daily life is mostly soda-lime glass made of quartz sand, soda ash, limestone, and feldspar as the main raw materials. During the annealing process of soda-lime glass, alkali ions will move to the glass surface, making ion exchange on the glass surface easy, and the glassy silica on the surface can be hydrolyzed.

Quartz sand

When soda-lime glass is stored in a humid environment, water or moisture will gradually diffuse from the surface of the glass to the inside of the glass. When the soluble sodium silicate in the surface layer is hydrolyzed, it will contact the carbonic acid formed by water and carbon dioxide., will produce orthosilicic acid which is weaker than carbonic acid. If the saturated orthosilicic acid (H4SiO4, hydrate of silicon dioxide) solution is left for a long time, there will be amorphous silica precipitation, the color is milky white, and it will appear as colloidal particles, precipitates or gels.

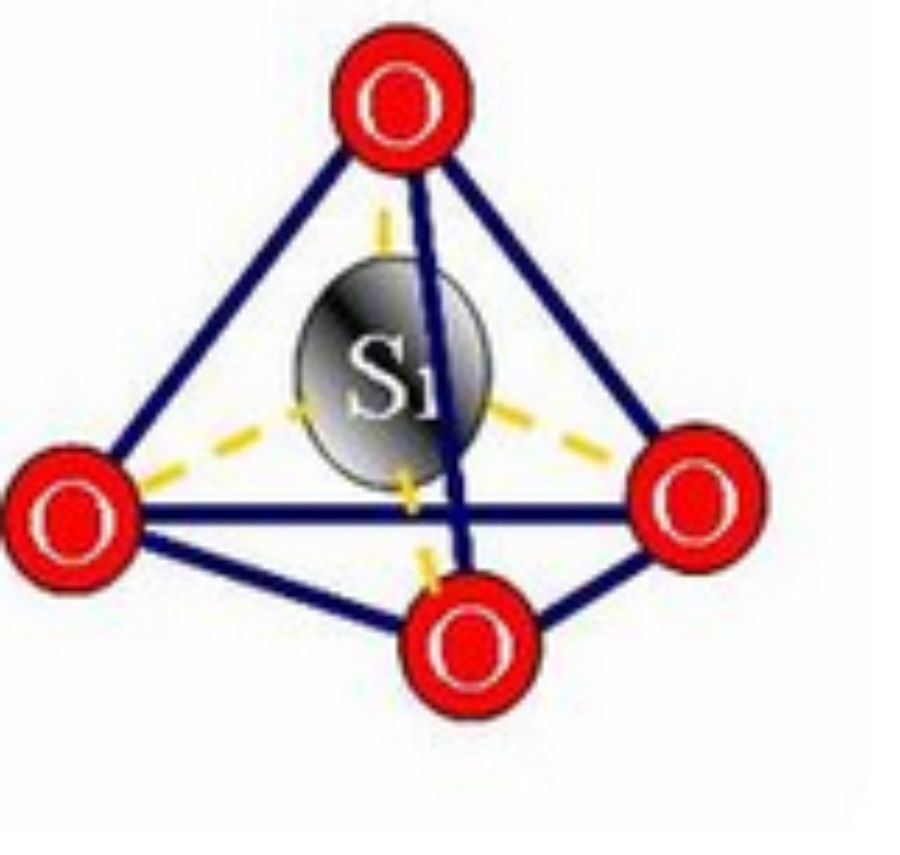

Structural diagram of orthosilicic acid (H4SiO4)

2. Stages of glass blooming

Glass blooming is generally divided into five stages:

(1) Water or moisture is adsorbed on the glass surface.

(2) Water or moisture diffuses into the glass.

(3) The soluble silicate in the surface layer is hydrolyzed and destroyed. First, sodium silicate and potassium silicate are hydrolyzed and destroyed to form caustic soda and separate silica.

Sodium silicate

(4) The separated silicon dioxide forms silica gel, which forms a protective film on the glass surface, which prevents further erosion.

(5) The caustic soda formed by hydrolysis reacts with carbon dioxide in the air to form sodium carbonate, which gathers on the glass surface to form soluble salts in the surface film. Due to its strong hygroscopicity, it absorbs water and deliquesces, and finally forms lye droplets. When the surrounding temperature and humidity change, the concentration of these droplets also changes. If the concentrated lye droplets are in contact with the glass for a long time, the gel-like silicon-oxygen film can be partially dissolved in it, causing severe local erosion on the glass surface and forming spots. This is a white alkali-rich ion group formed by the migration of sodium ions from the glass body and reaction with air.

caustic soda

3. The phenomenon of glass blooming

(1) White fog, white spots: slight blooming on the glass surface due to storage time, air humidity or glass quality problems.

White spot phenomenon in glass blooming

(2) Rainbow: When the white mist and white spots appear for a long time and are not dealt with in time, a rainbow will form. At this time, the blooming situation only stays on the glass surface and does not corrode into the glass.

Rainbow phenomenon in glass blooming

(3) Sulphurization: The appearance characteristics of glass blooming are the same as slight blooming, but the alkaline blooming components on the glass surface have been corroded into the glass, which belongs to severe blooming.

Sulfur change in glass blooming

(4) Paper printing: Like sulfur change, blooming is on the outside and inside of the glass, which is serious blooming.

The phenomenon of paper printing in glass blooming

The identification and inspection of blooming can observe the surface condition of the glass sample through the visual appearance method and spray wetting method. Under concentrated strong light, place the sample in reflected light and transmitted light or spray water mist to observe whether there are spots and fog on the glass surface. If spots and mist appear and cannot be removed with a cloth or water. It means that the glass sample has been blooming.

The degree of blooming depends on the condition of spots and fog: if a few spots and mist are observed with the naked eye under concentrated strong light, it belongs to slight blooming, and if many spots and light fog are observed, it belongs to medium blooming. If there is no concentrated beam of light, some spots and fog are observed with the naked eye, which is severe blooming.

4. Prevention and solution of glass blooming

(1) The phenomenon of glass blooming mainly occurs during storage or transportation after . In view of this situation, the following measures can be taken to prevent blooming:

① Add glass anti-blooming isolation powder when packing;

Glass anti-blooming isolation powder

② The glass should be stored in a well-ventilated warehouse;

③ It is not allowed to place the glass box directly on the wet ground in the warehouse;

④ It is not allowed to store glass outdoors and under direct sunlight.

glass warehouse

(2) If the glass has been blooming, a glass blooming remover should be used to remove the glass surface defects caused by the glass blooming.

The specific amount of glass blooming remover depends on the blooming situation. Wear rubber gloves, a mask and protective glasses for blooming removal operations. Use a sponge or cotton cloth to properly dip this product in the blooming glass and wipe it. Keep the liquid in the blooming place for 30 seconds to 3 minutes, and then rinse it off with clean water. That is, if it is severe blooming, the reaction time should be extended appropriately. The effect of blooming removal depends on the duration of glass blooming, the type of glass product, the type of glass blooming and the ratio of blooming remover.

But glass blooming remover is not a panacea, not all glass blooming can be completely removed. In order to reduce the loss of reputation of glass production enterprises and deep processing enterprises due to glass scrapping, the best way is to take preventive measures in advance, so that there will be no troubles.