As brands demand shorter delivery times for packaging materials, the spot demand from suppliers has highlighted the importance of post-processing steps for cosmetic packaging materials, especially in areas like graphic and textual silk screen printing. Whether it's plastic bottles, bottles, lipstick tubes, air cushion boxes, or bottles, ensuring the quality of these items is critical for the cosmetic packaging industry. The quality control processes for silk screen printing are essential to maintain high standards for products such as skin care packaging and other packaging materials.

For accurate testing of silk screen printing quality on cosmetic packaging products, the following environmental parameters should be maintained:

Luminance: 200-300LX (equivalent to a 40W fluorescent lamp at a distance of 750MM)

Inspection Angle: The visual direction of the inspector should be approximately 45° to the product surface. The inspection should take around 10 seconds.

Distance for Inspection:

Class A Surface (external surface that can be directly viewed): 400MM

Class B Surface (inconspicuous external areas): 500MM

Class C Surface (internal or non-visible surfaces): 800MM

Several common defects may occur during the silk screen printing process for skin care packaging, including:

Foreign Objects: Dust, dots, or filamentous particles adhering to the printed surface.

Exposed Background: Thin ink layers expose the underlying background color.

Misprinting: Incorrectly placed or missed printing on the product.

Blurred/Disconnected Prints: Uneven lines or partially disconnected characters due to poor printing results.

Uneven Ink Thickness: Ink thickness is inconsistent, affecting the clarity of the screen printed patterns.

Misalignment: Print positioning is off-center, causing misalignment on glass jars, plastic packaging, and other items.

Poor Adhesion: The silk screen print can be easily removed with adhesive tape.

Pinhole Defects: Small holes in the printed surface.

Scratches: Caused by insufficient post-print protection.

Miscellaneous Colors or Stains: Unwanted colors or stains on the printed surface.

Color Difference: Variations from the standard color palette.

Reliability testing ensures that cosmetic packaging meets stringent performance standards. The following are common tests:

High Temperature Storage Test

Storage Temperature: +66°C

Storage Time: 48 hours

Acceptance Criteria: No visible wrinkles, bubbles, cracks, or significant changes in color or gloss after 2 hours at room temperature.

Low Temperature Test

Storage Temperature: -40°C

Storage Time: 48 hours

Acceptance Criteria: No visible defects or changes in the printed surface.

High Temperature and Humidity Test

Storage Conditions: +66°C / 85% humidity

Storage Time: 96 hours

Acceptance Criteria: No visible changes after storage and 2 hours at room temperature.

Thermal Shock Test

Cycle Conditions: -40°C to +66°C, with a maximum transition time of 5 minutes per cycle, totaling 12 cycles.

Acceptance Criteria: No visible changes in the printed surface.

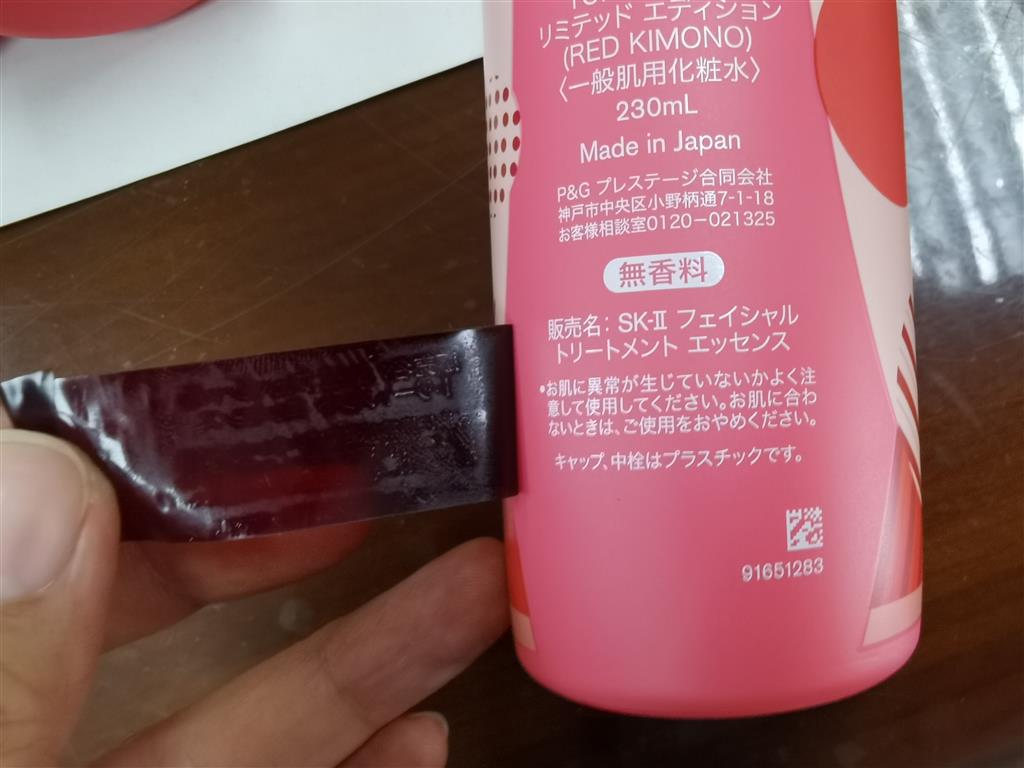

Silk/Pad Printing Adhesion Test

Test Tool: 3M616/600/810 tape

Test Method: Apply tape to the printed surface, press flat, and remove at a 90-degree angle.

Acceptance Criteria: No peeling or loss of print clarity.

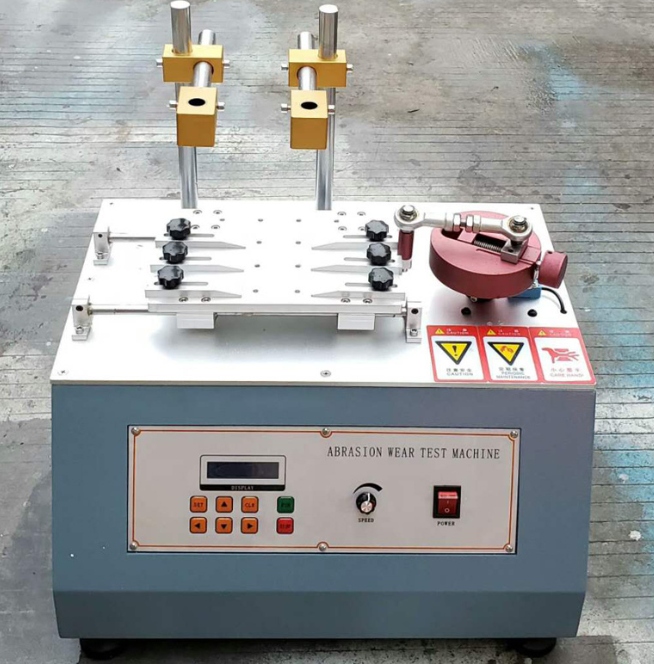

Friction Test

Test Tool: Eraser

Test Method: Rub the printed area with an eraser under a 500G force for 50 strokes.

Acceptance Criteria: No visible wear; print should remain clear and distinguishable.

Solvent Resistance Test (Isopropanol and Alcohol)

Test Method: Apply isopropanol or alcohol to the printed surface and rub for 20 cycles.

Acceptance Criteria: Print remains clear and intact without fading or discoloration.

Thumb Test

Test Method: Rub the printed surface with your thumb for 15 strokes under 3+0.5/-0KGF pressure.

Acceptance Criteria: No peeling, cracking, or ink adhesion failure.

75% Alcohol Test

Test Conditions: 5 or more samples, white cotton gauze soaked in 75% alcohol.

Test Procedure: Perform 30 round-trips over the printed pattern.

Acceptance Criteria: No peeling or ink failure; color fading is acceptable but print must remain clear.

95% Alcohol Test

Test Conditions: Similar to the 75% alcohol test, but with 95% alcohol.

Acceptance Criteria: The printed pattern should remain intact and clear.

810 Tape Test

Test Conditions: 5 samples, 810 tape.

Test Procedure: Apply tape, pull off at a 45° angle, and repeat 3 times.

Acceptance Criteria: No chipping or damage to the printed surface.

3M616/600 Tape Test

Test Procedure: Apply 3M616/600 tape, pull off quickly at a 45° angle.

Acceptance Criteria: No chipping or print damage.

250 Tape Test

Test Procedure: Use 250 adhesive tape, perform 3 consecutive tests.

Acceptance Criteria: The printed pattern should remain intact.

Gasoline Wipe Test

Test Conditions: Use a gasoline and alcohol mixture, 1.5KG fixture, and white cotton gauze.

Test Procedure: Wipe the printed surface 30 times.

Acceptance Criteria: No visible ink loss or pattern failure.

N-Hexane Wipe Test

Test Conditions: Similar to the gasoline wipe test, but with n-hexane solution.

Test Procedure: Repeat the wiping test 30 times.

Acceptance Criteria: The print should remain intact with only slight fading acceptable.

The quality control of silk screen printing in cosmetic packaging—whether for glass bottles, glass jars, plastic packaging, or perfume bottles—is crucial for maintaining product appeal and integrity. Through rigorous testing methods like compatibility tests, adhesion tests, and thermal shock tests, manufacturers can ensure that their skin care packaging products are reliable and meet high industry standards. By implementing proper quality control processes and using eco-friendly materials, packaging companies can meet both environmental and performance expectations in the cosmetic packaging sector.

As consumer demand for eco-friendly packaging rises, it is important for companies like Yafeng Packaging to ensure that their packaging printing methods, such as silk screen printing on plastic bottles and glass jars, uphold high standards of durability and aesthetic appeal, while also minimizing environmental impact.