Common Faults and Solutions in the Hot Stamping Process in the Cosmetics Industry

Hot stamping is a popular technique in the cosmetic industry, used to enhance the visual appeal of products, including bottles, plastic bottles, and packaging. The process involves transferring a metallic or colored foil onto a substrate using heat and pressure. However, achieving the perfect hot stamping effect depends on the coordination of temperature, pressure, and stamping speed. By mastering these parameters, manufacturers can ensure the quality of their cosmetic packaging. Here are common faults and solutions to improve hot stamping, especially for packaging like bottles, makeup containers, and cosmetic jars.

Main Causes and Solutions:

Several factors can contribute to weak hot stamping, including improper temperature, pressure, ink formulas, and the surface characteristics of the printed parts.

Low Temperature or Insufficient Pressure: Adjust the hot stamping temperature and pressure to suit the material and equipment. For instance, glass bottle stamping may require higher temperatures (190°C-220°C) than plastic bottles or flat substrates (100°C-120°C). Ensure the transfer properties of anodized aluminum align with the process.

Excessive Drying Oil: If too much drying oil is used in the ink, it can cause crystallization, preventing proper foil transfer. Reduce drying oil and re-press to remove the crystallized layer.

Use of Wax-Based Adhesives: Some adhesives contain wax that affects hot stamping adhesion. Absorb excess wax by pressing absorbent paper onto the printed material.

Surface Contaminants: Excess powder or additives like adhesive removers can hinder adhesion. These should be cleaned before the hot stamping process.

Incorrect Anodized Aluminum Selection: Choose the right type of anodized aluminum based on the printing area and material. For example, Yafeng Packaging’s custom cosmetic packaging often uses high-quality anodized aluminum for optimal hot stamping on glass perfume bottles and makeup containers.

Main Causes and Solutions:

This occurs when the anodized aluminum pulls off the printed ink or varnish during stamping.

Ink Not Fully Dried: Ensure the ink has dried completely before hot stamping. Use quick-drying inks or extend the drying time.

Insufficient Pressure: Use appropriate pressure during printing. The printing plate should be even and provide consistent pressure.

Low Ink Viscosity: Use inks with higher viscosity, particularly for printing large areas like those found on skincare packaging or makeup containers.

Main Causes and Solutions:

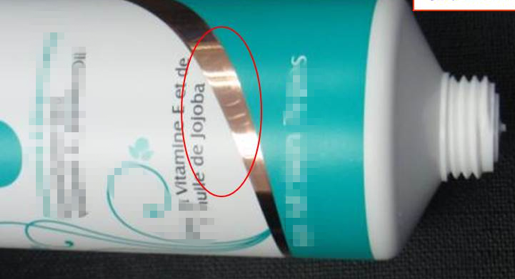

This happens when the hot stamping foil does not fully adhere to the substrate, exposing parts of the printed image.

Low Temperature or Pressure: Increase both the temperature and pressure if the foil is not transferring completely.

Excessively Dry Background Ink: If the background ink layer is too thick or dried out, it prevents proper foil transfer. Avoid excessive ink thickness and check for crystallization.

Incorrect Anodized Aluminum Type: Use the correct anodized aluminum for specific substrates like OPP or PET laminated paper often used in skincare and makeup packaging.

Main Causes and Solutions:

Blurry graphics typically occur due to insufficient pressure, uneven force, or incorrect foil transfer.

Insufficient Pressure: Ensure uniform pressure and check the quality of the printing plate and foil.

Temperature Too Low: A low hot stamping temperature may cause incomplete melting of the adhesive layer, leading to poor adhesion.

Speed Too Fast: If the stamping speed is too fast, the foil might not have enough time to transfer properly. Slow down the hot stamping process to improve results.

Main Causes and Solutions:

When the text or graphics appear blurry or distorted, it is likely caused by high temperatures.

Excessive Heat: Hot stamping temperatures that are too high can cause the foil to expand, leading to distortion. Ensure the temperature is adjusted based on the anodized aluminum properties.

Coked Foil: If the foil is exposed to high temperatures for too long, it can burn. Reduce the downtime between stamping runs.

Main Causes and Solutions:

This fault arises when the foil sticks to the printing plate, leading to smeared or unclear prints.

High Temperature: Lower the hot stamping temperature to avoid melting the foil or substrate.

Loose Foil or Incorrect Stamping Plate: Ensure the foil is properly aligned and the plate is well-maintained to prevent smearing.

Main Causes and Solutions:

Uneven edges, such as burrs, typically occur when the pressure is uneven across the plate.

Uneven Pressure: Ensure the printing plate is flat and uniformly supported. Adjust pressure settings to ensure even transfer across large areas, particularly in premium skincare packaging or perfume bottles where clarity is key.

Main Causes and Solutions:

This occurs when the stamping plate is damaged or the foil is not properly aligned with the design.

Plate Damage: Replace or repair any damaged plates.

Incorrect Foil Alignment: Ensure the foil is properly aligned with the printed graphics. Adjust the transport mechanism to prevent misalignment during the hot stamping process.

Main Causes and Solutions:

If the graphics appear dull, it may be due to excessive heat or improper processing.

High Temperature: Lower the temperature to prevent the anodized aluminum from losing its gloss.

Incorrect Process Sequence: Laminate before hot stamping to avoid damaging the foil’s surface gloss.

Main Causes and Solutions:

High temperatures can cause the anodized aluminum to discolor.

High Temperature: Lower the temperature to prevent discoloration of the foil. Installing a fan at the foil feeding area can also help maintain an even temperature.

Looking ahead, hot stamping in the cosmetic packaging industry is evolving with the introduction of cold stamping technology. Cold stamping does not require heat but uses pressure and special adhesives to transfer foil. While it is more economical than traditional hot stamping, it is not yet widely adopted due to its limitations in achieving the same gloss and effects, particularly on complex beauty packaging designs.

At Yafeng Packaging, we’re committed to delivering high-quality, custom cosmetic packaging solutions for premium brands in the skincare, makeup, and fragrance industries. Whether you're looking for custom glass bottles, skincare packaging, or perfume bottles, we ensure superior hot stamping quality that enhances your product's visual appeal and brand identity.

For more information on how we can elevate your cosmetic packaging with high-quality hot stamping, contact us at YafengPackaging, your trusted partner for all your cosmetic packaging needs.