Introduction of Skin Care Product Airless Bottles

Good skin care products contain amino acids, proteins and other substances. These substances are very afraid of dust and bacteria, and are easily contaminated. Once contaminated, they will not only lose their intended effect, but also become very harmful. The airless bottle can completely isolate the contents from the air, preventing the product from oxidizing, deteriorating, and breeding bacteria due to exposure to air. Its high-tech functions ensure product quality.

Product definition

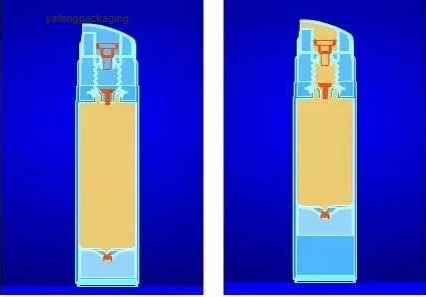

An airless bottle is a high-end bottle consisting of a cap, a pressure head, a cylindrical or ellipsoid container body, a base and a piston that is placed at the bottom of the bottle body. Its launch complies with the latest development trend of skin care products and can effectively protect the freshness and quality of products. However, due to the complex structure and high cost of airless bottles, the use of airless bottle packaging is limited to a limited number of categories of products, and cannot be fully rolled out in the market to meet the needs of different levels of skin care product packaging.

Manufacturing process

1. Design principle

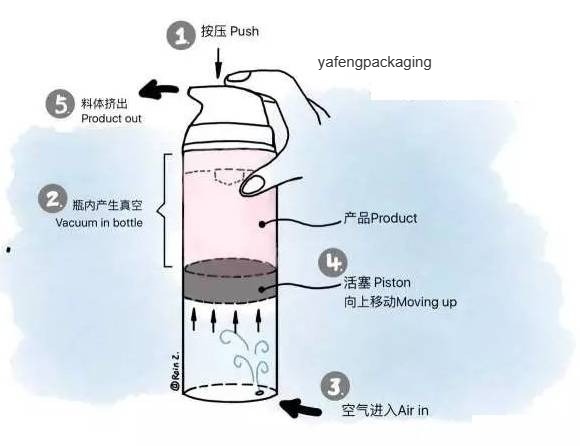

The design principle of the airless bottle is to use the contraction force of the spring and prevent air from entering the bottle to create an airless state. Airless packaging uses the principle of dividing the inner cavity to squeeze out the contents, and uses atmospheric pressure to push the piston at the bottom of the bottle. go ahead. When the inner diaphragm moves upward to the inside of the bottle, a pressure is formed. At this time, the content is in a airless state close to 100 %. However, because the spring force and atmospheric pressure cannot give enough force, the piston cannot fit with the bottle wall. If it is too tight, otherwise the piston will be unable to rise and move forward due to excessive resistance; on the contrary, if the piston is to move forward easily, material leakage will occur. Therefore, the airless bottle requires very high professionalism in the production process.

2. Product features

Airless packaging also provides precise dosage control. Once the discharge hole and specific airless pressure are set, regardless of the shape of the matching pressure head, the dosage will be accurate and quantitative each time. Therefore, the dosage can be adjusted by changing a certain part, from a few microliters or a few milliliters, according to the needs of the product. Once the airless packaging is assembled, from the self-filling packaging to the consumer's use, almost negligible air can enter the container and contaminate or decompose the contents. This is the advantage of airless packaging - it provides a safe packaging container for the product, avoiding contact with air, reducing possible changes and oxidation. In particular, there is an urgent need to protect delicate natural ingredients, and there are calls to avoid adding preservatives. Among them, airless packaging is even more important for extending the shelf life of products.

Structure overview

a) According to structure: ordinary vacuum bottle, rotating vacuum bottle, conjoined vacuum bottle, double-tube vacuum bottle

b) According to shape: cylindrical, square, cylindrical is the most common.

Vacuum bottles are usually cylindrical, with specifications ranging from 15ml to 50ml, and some have 100ml. The overall capacity is small. It relies on the principle of atmospheric pressure to avoid contamination of cosmetics during use. Vacuum bottles include anodized aluminum, plastic plating and colored plastics. The price is more expensive than other ordinary containers, and the ordinary order quantity requirements are not high.

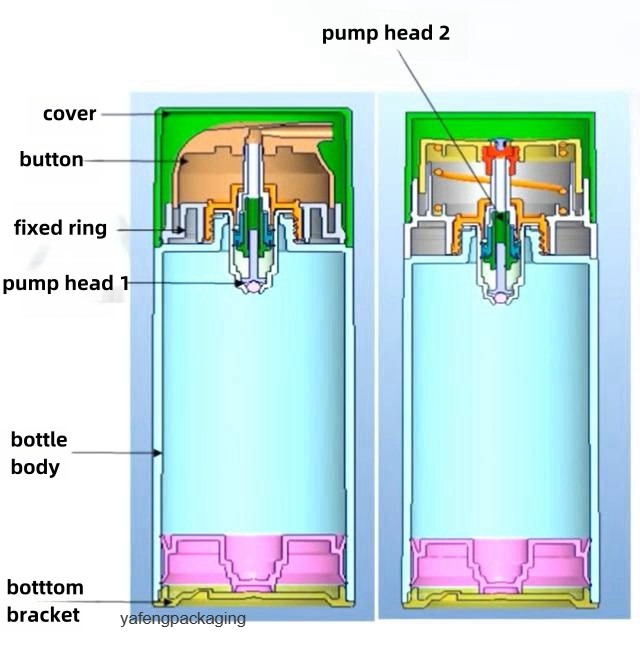

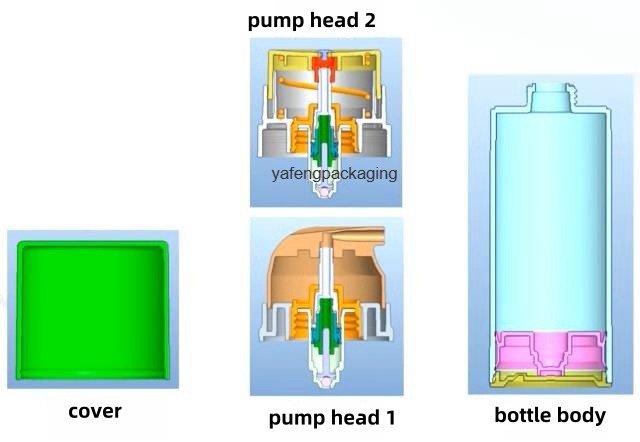

2. Product structure reference

3. Reference to the structural matching diagram

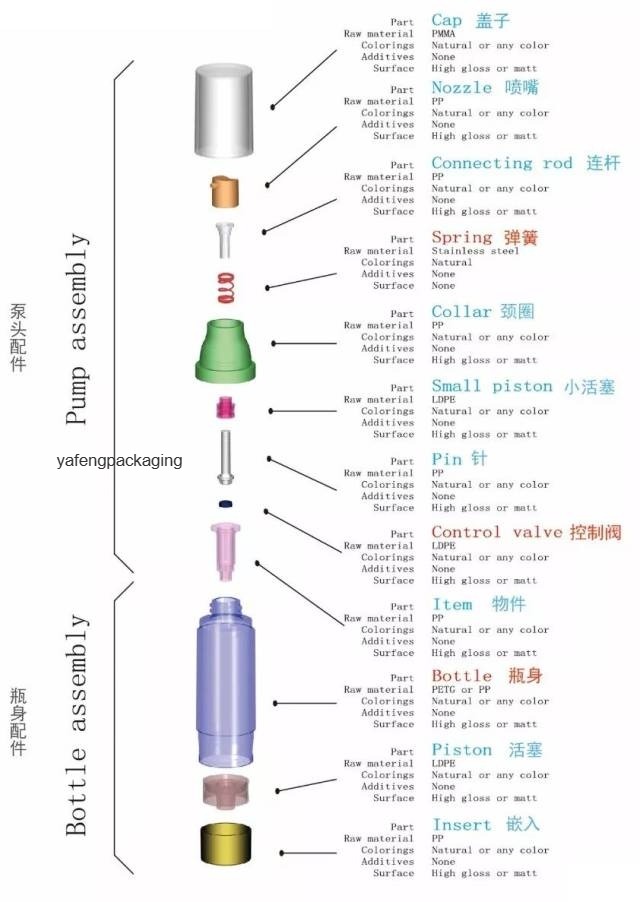

The pump head is the main accessory of the airless bottle. Generally, they include: cover, nozzle, connecting rod, gasket, piston, spring, valve, pump body, straw, valve ball (steel ball, ball), etc. Bottle caps and dust covers can be colored, electroplated, and covered with electroplated aluminum rings. Since a set of pump heads involves many molds and the order quantity is large, the minimum order quantity is 10,000 to 20,000. The off-season delivery period is 15 to 20 days after the sample is confirmed. White and general types are often in stock. Dispenser customers rarely make their own molds, and they need more molds, which is more expensive.

4. Other types of airless bottles:

All-plastic self-closing valve airless bottles are airless bottles containing skin care products. The lower end of the airless bottle is a carrying disc that can move up and down in the bottle body. There is a round hole at the bottom of the airless bottle. The bottom of the disc is air and the top is skin care products. The skin care products are sucked out from the top by the pump, and the carrying disc continues to rise. When the skin care products are used up, the disc rises to the top of the bottle.

Purchasing points

1. Airless pump testing

An airless pump requires these components: spring, sealing valve (or sealing ball), piston, and pump shell (the size determines the amount of each pump). The difficulty of the airless pump lies in the sealing performance of each component. Since the air tightness is required to be extremely high, the requirements for the mold and parts are relatively high. Otherwise, it is easy for the material body to not come out.

2. Air tightness of airless bottle

The friction between the inner piston and the bottle is very important to the air tightness. The friction is the core of the airless bottle and is related to both the air tightness and the up and down movement of the piston. So you should also pay attention to this.

3. Determine the quality of airless bottles

Filling ensures that the material body does not pass the lower edge of the cylinder, the pump number is stable, the discharge volume is stable, and the air tightness test condition is -0.08Mpa. About 10 minutes, both front and side placement, is the energy of the whole bottle of material body stable? Finish spraying.