Some Basics About Pumps

Lotion pumps are essential components for dispensing the contents of cosmetic , whether it's a plastic bottle or a container. The lotion pump plays a crucial role in personal care product packaging, as it directly influences the consumer experience. This tool is integral to packaging, ensuring that the liquid can be dispensed easily and effectively, whether for skincare, shampoo, lotion bottles, or other cosmetic containers.

A lotion pump is a liquid dispenser used in cosmetic packaging. It operates based on the principle of atmospheric pressure to pump out the liquid from plastic bottles, glass bottles, or cosmetic containers. When pressed, the pump draws in outside air to balance the pressure inside the container, enabling the product to be dispensed through the nozzle.

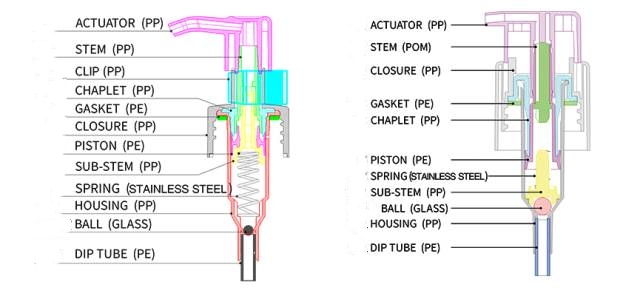

A conventional lotion pump is typically composed of several parts, including the nozzle or head, upper pump column, lock cap, gaskets, bottle cap, pump plug, lower pump column, springs, pump body, glass balls, and straw. Depending on the design of the pump, certain parts may vary, but the essential function remains the same: to effectively dispense the contents. Whether it's for a lotion pump, foam bottle, or bottle, the functionality of the pump remains a priority in cosmetic packaging.

The majority of pump components are made from plastic materials like PE, PP, and LDPE. These are shaped through injection molding. Other parts like the glass beads, springs, and gaskets are typically sourced externally. The pump's components can undergo various treatments like electroplating, anodizing, or spraying. The surface of the pump head and the nozzle can be decorated using techniques such as gold or silver stamping, silk-screen printing, or pad printing, allowing for customization on skincare packaging, cosmetic bottles, and more.

Lotion pumps are categorized based on several factors:

Diameter: Common sizes include Ф18, Ф20, Ф22, Ф24, Ф28, Ф33, Ф38, etc.

Lock Head Type: Options include guide block lock head, thread lock head, clip lock head, and no lock head.

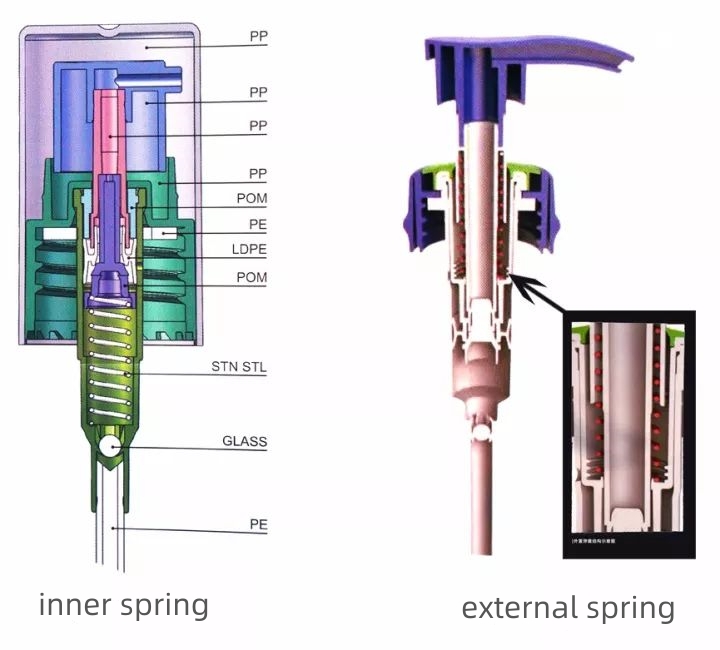

Spring Type: There are external springs, plastic springs, anti-water emulsion pumps, and high-viscosity pumps.

Pumping Method: Lotion pumps can be divided into vacuum bottles and straw-type pumps.

Pumping Amount: Different pumps are designed to dispense varying amounts of liquid, including 0.15cc, 0.2cc, 0.5cc, 1.0cc, 3.5cc, and higher volumes.

When the user presses the pressure handle, the volume in the spring chamber decreases, increasing the pressure. This forces the liquid into the nozzle chamber through the valve core. The liquid is then sprayed out through the nozzle. When the pressure is released, the volume in the spring chamber increases, creating negative pressure, which opens the ball and allows the liquid to refill the spring chamber. Each press stores liquid in the valve body, which is then dispensed when the handle is pressed again.

Key performance metrics for lotion pumps include air pressure times, pump output, downforce, pressure head opening torque, rebound speed, and water intake capacity. These factors are crucial for ensuring that the pump functions efficiently, providing the right amount of product with each press, whether it's for a lotion bottle, foam bottle, or cosmetic packaging.

A key distinction between lotion pumps is the spring type. An outer spring does not come into contact with the contents, preventing contamination of the product. This is particularly important for skincare and cosmetic packaging, where maintaining the integrity of the product is essential.

Lotion pumps are extensively used in the cosmetics industry, particularly in the packaging of personal care products such as shampoos, bath milk, moisturizers, serums, sunscreens, BB , liquid foundation, facial cleansers, hand sanitizers, and more. Lotion pumps are integral to ensuring a controlled and hygienic dispensing process in cosmetic bottles, skincare packaging, and personal care product containers.

Pumping EffectThe sealing of the glass bead or steel ball under the spring is critical. If leakage occurs, some liquid will spill back into the bottle when the pressure handle is pressed, negatively affecting the spray or pump function. The sealing ring at the top of the valve body also plays a vital role in ensuring proper suction and storage of liquid in the pump mechanism.

Fit Between the Pressure Handle and Valve CoreA tight fit between the pressure handle and valve core is essential to prevent leakage. A loose fit can cause resistance when liquid is dispensed, and may also lead to product backflow, affecting the spray or dispensing effect.

Design of NozzlesThe design and functionality of the nozzle directly impact the spray pattern and the effectiveness of the pump. For packaging products like lotions, shampoos, or foam bottles, a well-designed nozzle ensures a smooth, even spray, which enhances the user experience.

Mold CostGiven the complexity of the lotion pump's design and the number of components involved, the cost of mold development is relatively high. This cost must be considered when manufacturing plastic bottles, glass bottles, and other cosmetic packaging products with pumps.

Lotion pumps are an indispensable part of modern cosmetic packaging. Whether it’s for a skincare bottle, shampoo bottle, or foam bottle, these pumps ensure that personal care products can be dispensed efficiently and hygienically. From the materials used in the pump to the intricacies of the manufacturing process, understanding the fundamentals of lotion pumps can help businesses select the right pumps for their cosmetic products, ensuring quality, performance, and a positive consumer experience.

By incorporating quality lotion pumps into their packaging, companies can enhance the appeal and functionality of their cosmetic packaging, offering users an easy, efficient way to access their favorite products.