What is PCR and PIR Plastic?

PCR: Post-Consumer Recycled Plastic

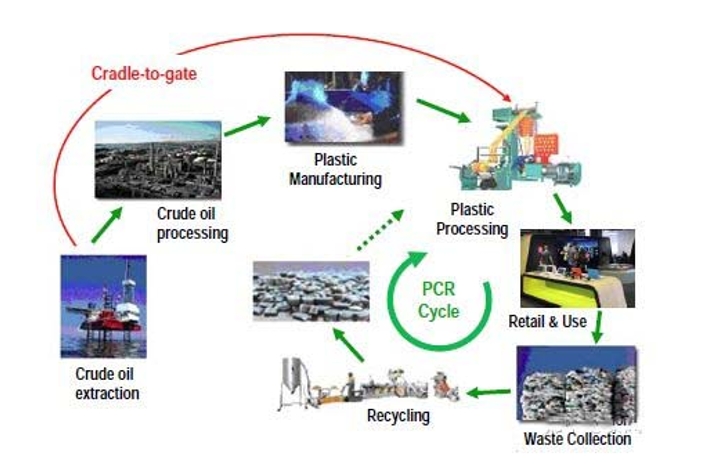

PCR (Post-Consumer Recycled) plastic refers to plastic materials that have been used by consumers and then recycled for reuse. These materials are primarily sourced from plastic bottles, skin care product bottles, and other types of plastic that are discarded after use. The goal of post-consumer recycling is to prevent these used plastics from being wasted and instead recycle them into new products, helping to reduce environmental impact and promote sustainability in industries like cosmetic packaging.

How is PCR Plastic Made?

The general process for recycling post-consumer plastics involves the following steps:

Pretreatment: This includes dismantling, sorting, and cleaning the plastic.

Crushing: The plastic is crushed into smaller pieces.

Melting: The crushed plastic is melted down into a liquid form.

Granulation: The melted plastic is then shaped into small pellets, which can be used in the production of plastic packaging, including cosmetic packaging.

This process allows skin care packaging and other plastic packaging products to be made from recycled materials, reducing the demand for virgin plastic.

What is GRS-Certified PCR Material?

The Global Recycling Standard (GRS) certification ensures that products meet rigorous environmental and social standards. For cosmetic packaging, obtaining GRS certification means that a product is made with at least 20% recycled content, including PCR plastic. This certification verifies that products are made in accordance with sustainable practices, including limiting the use of chemicals, maintaining traceability throughout the production process, and ensuring compliance with environmental standards such as water management, waste discharge, and pollution control.

The GRS certification is particularly important in the context of eco-friendly packaging, as it assures consumers that the plastic packaging used in their products is not only recyclable but is also produced in an environmentally responsible way.

China’s Role in PCR and Plastic Recycling

China has emerged as the largest producer, importer, and consumer of synthetic resins globally. The Chinese government has made building a circular economy a national priority, encouraging the recycling of plastic packaging materials and the use of eco-friendly solutions across industries. As part of this, China's plastic recycling industry plays a key role in processing post-consumer plastics and converting them into valuable raw materials that can be reused in cosmetic packaging and other plastic packaging products.

The Importance of Recycling Waste Plastics

Recycling post-consumer plastics is a crucial step toward reducing plastic waste and conserving resources. For instance, recycling just one ton of plastic can save up to six tons of oil resources. This highlights the importance of recycling plastic bottles, skin care packaging, and other forms of plastic packaging in order to reduce environmental damage and promote resource conservation.

China’s plastic products industry is rapidly developing, yet the rate of plastic recycling remains low. Improving the recycling and reuse of plastic packaging is vital to adjusting the industrial structure and promoting eco-friendly manufacturing practices in the cosmetic packaging sector.

PIR: Post-Industrial Recycled Plastic

Unlike PCR, PIR (Post-Industrial Recycled) plastic is derived from waste generated during the manufacturing process itself. This includes leftover materials, defective products, and nozzle waste from injection molding processes. PIR plastic is often easier to process since it is free from contaminants, and it can be recycled and reused directly within the factory. After being crushed, PIR plastic is granulated and ready to be used again in the production of cosmetic packaging, plastic packaging, and other industrial products.

The Environmental Impact of Plastic Waste

In recent years, awareness of the environmental impact of plastic waste, particularly in oceans, has increased. Every year, approximately 8 million tons of plastic are dumped into the ocean, contributing to the growing plastic pollution crisis. This plastic waste not only harms marine life but also poses a threat to humans. Over time, plastic breaks down into smaller particles, which are difficult to clean up and can enter the food chain.

The European Union has introduced regulations requiring that by 2025, plastic packaging must contain at least 25% PCR materials. This move is in response to the overwhelming impact of plastic pollution and highlights the increasing demand for eco-friendly packaging solutions, including the use of PCR and PIR plastic.

The Future of PCR and Sustainable Cosmetic Packaging

As plastic pollution continues to grow, the need for sustainable cosmetic packaging and skin care packaging becomes even more urgent. PCR plastic plays a vital role in helping brands reduce their reliance on virgin plastic and minimize their environmental footprint. By utilizing post-consumer recycled materials, cosmetic packaging can be made more eco-friendly and contribute to a circular economy.

Big cosmetic brands are already implementing PCR projects and investing in plastic recycling solutions to comply with regulations and meet consumer demand for eco-friendly packaging. As more brands adopt PCR and PIR plastic for their cosmetic packaging and skin care packaging products, the industry is moving toward a more sustainable future, where recycling plays a critical role in reducing plastic waste and conserving resources.

In conclusion, PCR and PIR plastic are essential to the future of eco-friendly packaging, especially in the cosmetic packaging sector. By adopting recycled plastic solutions, companies can reduce their environmental impact while meeting consumer demand for sustainable and responsible packaging.